What is Hot Dip Galvanizing?

Hot-dip galvanizing (HDG), is the process of dipping fabricated steel into a kettle or vat containing molten zinc. The process is inherently simple which provides a distinct advantage over other corrosion protection methods. While the steel is in the kettle, the iron in the steel metallurgically reacts with the molten zinc to form a tightly-bonded alloy coating that provides superior corrosion protection to steel. Read More

ULTIMATE GALVANIZING STANDARD PRACTICE AND SERVICES

Technical Support

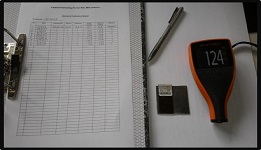

UGS’s Technical Department enables us to maintain tight process controls thus assuring desired results.

SOPs

UGS to produce and deliver cost effective, high quality coatings of hot-dip galvanized products

03-8060 1973 | 03-8069 1386

03-8060 1973 | 03-8069 1386